Caterpillar Launches Industry's First Commercial 789D Autonomous Water Truck

April 16,2025

Dust pollution has been a long-standing problem in open-pit mining operations. These dust particles not only pose a serious threat to the physical health of workers, but also affect the normal operation of equipment, reduce production efficiency, and even cause safety accidents. Caterpillar recently launched the industry's first commercial 789D unmanned sprinkler truck, bringing a new solution for dust control in open-pit mines. What is unique about this device that combines advanced technology and innovative design? How does it cope with the complex working environment of open-pit mines? Let's explore the truth.

1. Open pit mine dust source: 'invisible killer'

There are many stages in open-pit mining operations, and each stage may generate a large amount of dust. During drilling operations, the drill bit rubs violently against the rock, producing a continuous stream of dust that floats into the air. The blasting operation instantly releases enormous energy, shattering the rocks and causing the dust to spread rapidly like dark clouds. During shoveling operations, the loading, unloading, and flipping of ores will raise a large amount of dust. During transportation, vehicle movement not only generates dust due to friction between the wheels and the ground, but also causes material leakage due to body vibration, further exacerbating dust pollution.

These dust particles pose a great threat. Long term inhalation of dust containing harmful substances such as free silica by workers can easily lead to respiratory diseases such as pneumoconiosis, seriously damaging their physical health. Dust can also reduce visibility at work sites, interfere with drivers' vision, and increase the risk of accidents such as vehicle collisions and rollovers. At the same time, dust adheres to the surface of equipment and enters the interior, accelerating equipment wear, shortening equipment service life, and significantly increasing maintenance costs. According to industry data, equipment failures and maintenance costs caused by dust pollution account for a relatively high proportion of operating costs in open-pit mines. Therefore, it is urgent to control dust pollution in open-pit mines.

2. 789D unmanned sprinkler truck

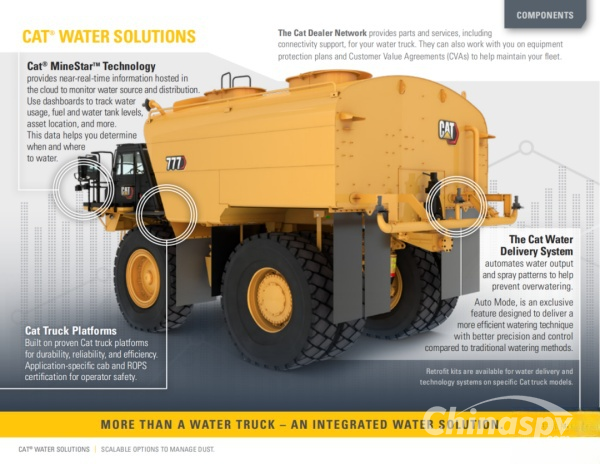

The Caterpillar 789D unmanned sprinkler truck is designed specifically for the complex environment of open-pit mines, integrating multiple advanced technologies and delivering outstanding performance.

Strong power and stable chassis

The vehicle is equipped with a powerful Cat 3516C HD engine, with a net power of 1468kW, which can provide ample power for the vehicle to drive on complex road conditions in mines. Whether climbing steep slopes or moving forward on rugged roads, it can be easily handled. The engine adopts advanced fuel injection and combustion optimization technology, which reduces fuel consumption and meets strict emission standards, reducing environmental pollution.

Its chassis is built on the 789D mining truck chassis, with excellent stability and durability. The frame made of high-strength steel can withstand huge impact forces and complex stress changes, and long-term bumps and vibrations will not affect the structural integrity. The high-quality suspension system effectively buffers road bumps, improves driving comfort, ensures good contact between tires and the ground, enhances handling and driving safety. Even when fully loaded, the vehicle can travel steadily, laying a solid foundation for watering operations.

Intelligent and precise sprinkler system

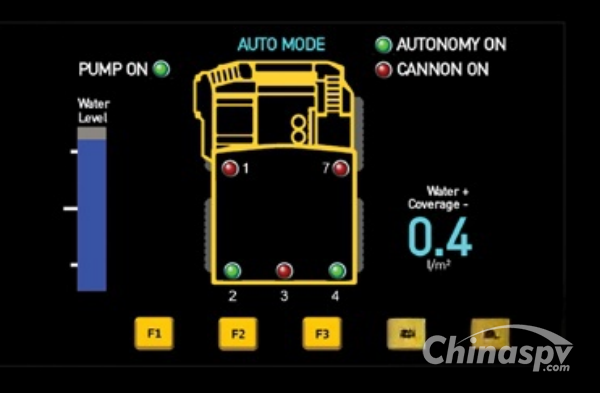

The Cat Water Delivery System (WDS) is the core highlight of this vehicle. It can automatically adjust the water flow and spray mode according to the vehicle driving speed, dust concentration in the operation area and other factors. When the vehicle is traveling at a high speed, the system automatically increases the water flow rate to suppress the dust generated during high-speed driving; When turning or passing the area with dense personnel and equipment, the water flow and spray range will be automatically reduced to avoid impact.

The nozzle adopts variable aperture technology, which can adjust the opening size according to actual needs. When spraying water on a large area, the nozzle opening increases to achieve efficient coverage; When precision spray, the opening is reduced to ensure that the water mist is accurately sprayed to the target area. This precise watering control not only improves the watering effect but also saves water resources. According to testing, compared to traditional sprinkler trucks, it can save 25% -50% of water and effectively reduce the cost of water in mines.

Advanced autonomous driving technology

The unmanned technology of Caterpillar's unmanned water truck enables it to operate autonomously in mines. With the help of high-precision GPS positioning systems, LiDAR, and cameras, vehicles can perceive their own position and surrounding environment information in real time. Through complex algorithms and control systems, automatically plan driving routes, cleverly avoid obstacles, and ensure driving safety.

During homework, the vehicle automatically completes the watering task according to the preset program. It can spray water in different areas and time periods according to the actual needs of the mine. When encountering other work vehicles or personnel, it will automatically slow down or avoid to ensure safe and smooth operation. Autonomous driving technology has improved work efficiency, reduced the impact of human factors, and lowered labor intensity and safety risks.

3. Supporting system: Collaborative operation, efficient operation

The efficient operation of Caterpillar's unmanned sprinkler truck relies on a series of collaborative supporting systems.

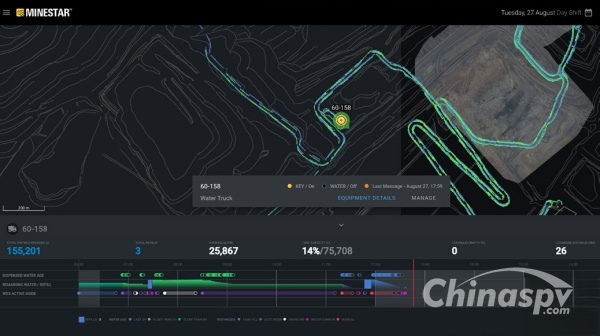

Cat MineStar Technology: Intelligent Management and Monitoring

Cat MineStar technology is deeply integrated with unmanned sprinkler trucks to achieve remote monitoring and intelligent management. Through this technology, mine managers can obtain real-time information such as vehicle position, driving speed, water flow, spray status, and can also remotely control and dispatch vehicles.

In the monitoring center, management personnel can clearly grasp the real-time operation of each sprinkler truck through the large screen. If the dust concentration in a certain area is found to be too high, the nearby sprinkler truck can be operated through Cat MineStar technical instructions. The system can also analyze vehicle operation data to provide data support for optimizing sprinkler operation plans and improving efficiency. By analyzing the driving route and watering time, adjusting the work schedule reasonably, reducing the idle time of vehicles, and improving resource utilization.

Automatic water addition system: efficient and convenient, saving time

The automatic water addition system is an important part of improving the efficiency of sprinkler truck operations. This system achieves automatic water addition during vehicle operation without the need for manual intervention. When the sprinkler truck approaches the water station, the system automatically communicates with the water station equipment to complete the preparation before adding water. When reaching the water filling position, the water filling pipeline automatically connects to the water tank to start adding water. When the set water level is reached, it automatically stops to prevent the water tank from overflowing.

The automatic water adding system greatly saves water adding time and improves vehicle operation efficiency. Traditional sprinkler trucks are time-consuming and labor-intensive to manually add water, and are prone to situations of excessive or insufficient water addition. The automatic water addition system enables the sprinkler truck to quickly complete the water addition task, return to the work area quickly, reduce downtime, and improve the overall production efficiency of the mine.

Maintenance system: Extend equipment lifespan and reduce costs

The maintenance system of Caterpillar's unmanned sprinkler truck can monitor the real-time operation status of key components and systems of the vehicle, detect potential faults and hidden dangers in advance, and issue timely alarms. By analyzing the operational data of components such as the engine, chassis, and sprinkler system, predict component wear and potential failures, and provide accurate maintenance recommendations for maintenance personnel.

In daily maintenance, the system automatically generates maintenance plans based on the vehicle's running time and mileage. Maintenance personnel shall perform timely maintenance and repair according to the plan, replace worn parts, and ensure that the vehicle is always in good operating condition. This preventive maintenance method extends the service life of vehicles and reduces maintenance costs. After adopting this system, the frequency and cost of vehicle maintenance have been significantly reduced, saving mining enterprises a lot of money.

4. Impact and Prospect

The Caterpillar 789D unmanned sprinkler truck has set a new benchmark for the open-pit mining industry with advanced technology and innovative design, driving the industry to increase research and development investment in unmanned driving and intelligent sprinkler technology, and promoting the rapid development of related technologies. In the increasingly strict environmental requirements, the application of 789D unmanned sprinkler truck will promote the construction of green mines, effectively control dust pollution, reduce the impact on the surrounding environment, and protect ecological balance. The intelligent water-saving and energy-saving technology of vehicles conforms to the concept of sustainable development.

Source : www.chinaspv.com.cn

Editor : Amicia

Views:3510