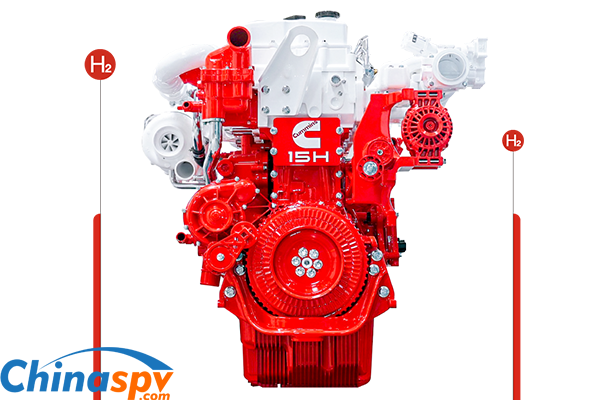

Cummins' Hydrogen Internal Combustion Engine

July 27,2023

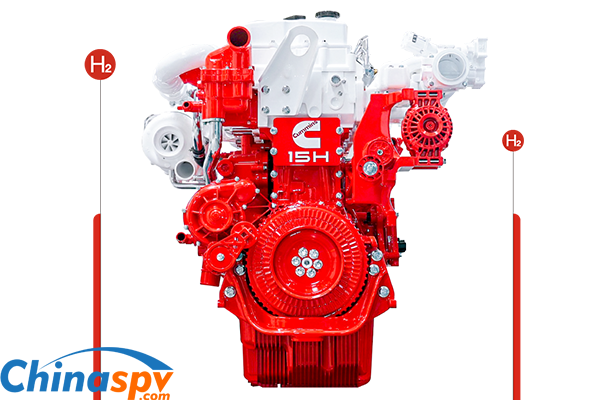

July 27, 2023, China, Recently, Cummins successfully ignited its 15L hydrogen internal combustion engine at the new East Asia R&D Center.

The Cummins 15L hydrogen internal combustion engine is based on the 15L global platform, which consolidates Cummins' global R&D resources and is customized for heavy-duty truck applications in China. The hydrogen internal combustion engine test bench in the Hydrogen Power Building can provide a maximum hydrogen gas supply of 5.5 Mpa. The laboratory's emission testing equipment has undergone special modifications for hydrogen testing, ensuring high safety factors and strong testing capabilities. Furthermore, this versatile test bench supports the development and testing of multiple fuel systems, including diesel and natural gas engines that use low-carbon fuels, better meeting the diverse needs of powertrain development.

The hydrogen internal combustion engine test bench in the Hydrogen Power Building can provide a maximum hydrogen gas supply of 5.5 Mpa. The laboratory's emission testing equipment has undergone special modifications for hydrogen testing, ensuring high safety factors and strong testing capabilities. Furthermore, this versatile test bench supports the development and testing of multiple fuel systems, including diesel and natural gas engines that use low-carbon fuels, better meeting the diverse needs of powertrain development.

Cummins' 15L hydrogen internal combustion engine incorporates several innovative technologies, such as in-cylinder direct injection and lean combustion. The basic engine's burst pressure capability reaches 250 bar. With an industry-leading combustion chamber design and a pent roof-based tumble combustion system, the engine achieves highly efficient hydrogen combustion and improved power transmission. Leveraging advanced in-cylinder direct injection technology with a maximum injection pressure of 40 bar significantly enhances efficiency. The engine can deliver a maximum power of 550 horsepower, offering robust performance to excel in various operating conditions.

The Cummins 15L hydrogen internal combustion engine is based on the 15L global platform, which consolidates Cummins' global R&D resources and is customized for heavy-duty truck applications in China.

Cummins' 15L hydrogen internal combustion engine incorporates several innovative technologies, such as in-cylinder direct injection and lean combustion. The basic engine's burst pressure capability reaches 250 bar. With an industry-leading combustion chamber design and a pent roof-based tumble combustion system, the engine achieves highly efficient hydrogen combustion and improved power transmission. Leveraging advanced in-cylinder direct injection technology with a maximum injection pressure of 40 bar significantly enhances efficiency. The engine can deliver a maximum power of 550 horsepower, offering robust performance to excel in various operating conditions.

Source : www.chinaspv.com

Editor : Mark

Views:3355